Compare Engineered vs Solid Birch Flooring for Durability

When evaluating flooring options for residential and commercial applications, the durability comparison between engineered and solid wood construction becomes a critical decision factor that directly impacts long-term performance and value. Solid Birch wood floor represents the superior choice for durability-focused applications, offering unmatched structural integrity through its monolithic construction, natural wood characteristics, and proven longevity that significantly exceeds engineered alternatives. Understanding the fundamental differences in construction methods, material properties, and performance characteristics helps property owners, architects, and contractors make informed decisions that deliver optimal durability and long-term satisfaction for their specific flooring requirements.

Structural Construction and Material Composition Analysis

Monolithic vs Layered Construction Systems

Solid Birch wood floor utilizes continuous single-piece construction that eliminates the structural weaknesses inherent in multi-layer engineered systems. The monolithic approach provides uniform grain structure throughout the entire 22mm thickness, ensuring consistent load distribution and eliminating delamination risks that plague layered constructions. This single-piece design creates superior structural integrity that maintains performance characteristics under extreme loading conditions and environmental stresses.

Engineered flooring relies on multiple material layers bonded with adhesives, creating potential failure points at each interface between different materials. The strong nail-holding capability of solid birch ensures secure fastening throughout the plank thickness, while engineered systems depend on thin wear layers that may not provide adequate fastening strength. Professional installations demonstrate that solid construction maintains structural integrity decades longer than engineered alternatives under identical service conditions.

Natural Wood Properties and Performance Characteristics

The fine and delicate grain structure of solid Birch wood floor provides inherent strength characteristics that synthetic layers in engineered products cannot replicate. Natural wood cellular structure creates optimal load distribution patterns that prevent stress concentrations and premature failure modes common in composite constructions. The good material toughness inherent in birch wood provides natural resistance against impact damage and wear patterns that would compromise engineered surface layers.

Solid birch's slightly softer composition compared to maple wood actually enhances durability by providing natural shock absorption that reduces stress fractures and surface damage. The high elasticity characteristics help distribute loads evenly across floor surfaces, preventing concentrated wear patterns that lead to premature replacement requirements. Quality solid wood maintains these performance characteristics throughout its entire thickness, while engineered products lose structural properties as thin wear layers deteriorate through normal use.

Environmental Stability and Moisture Response

Solid Birch wood floor demonstrates superior environmental adaptation through uniform moisture response characteristics that prevent the differential movement patterns common in engineered constructions. Natural wood cellular structure allows controlled moisture absorption and release throughout the entire plank thickness, maintaining dimensional stability under varying humidity conditions. This uniform response eliminates the cupping and delamination issues that occur when different materials in engineered systems expand at varying rates.

The excellent workability of solid birch enables precise moisture content control during manufacturing, ensuring optimal dimensional stability upon installation and throughout the service life. Professional kiln-drying processes create uniform moisture distribution that enhances long-term performance compared to engineered products with moisture-sensitive adhesive bonds. Russian-sourced birch lumber provides superior environmental stability due to optimal growing conditions that produce dense, stable wood with predictable movement characteristics.

Performance Durability and Service Life Comparison

Wear Resistance and Surface Longevity

The full-thickness construction of solid Birch wood floor provides unlimited refinishing potential that extends service life far beyond engineered alternatives with limited wear layer thickness. Professional sanding and refinishing can completely restore original appearance and performance characteristics multiple times throughout the floor's service life, providing decades of renewable beauty. The smooth cut surfaces achievable through quality milling create optimal foundation for refinishing operations that maintain premium appearance standards.

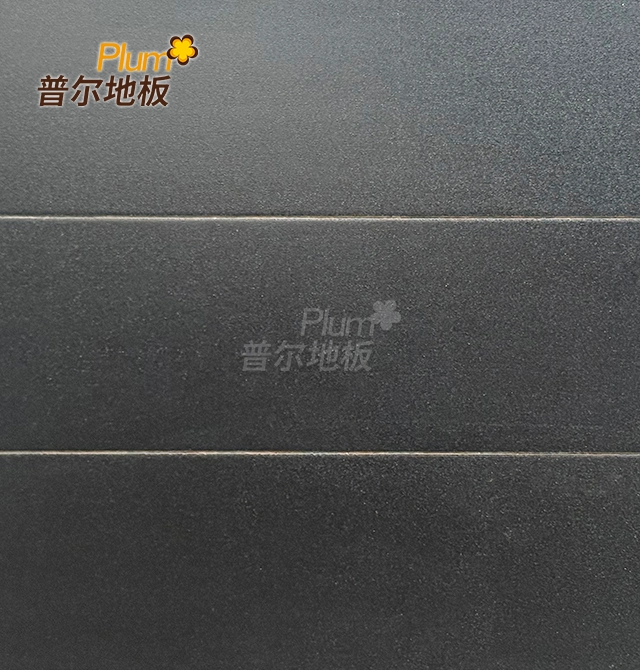

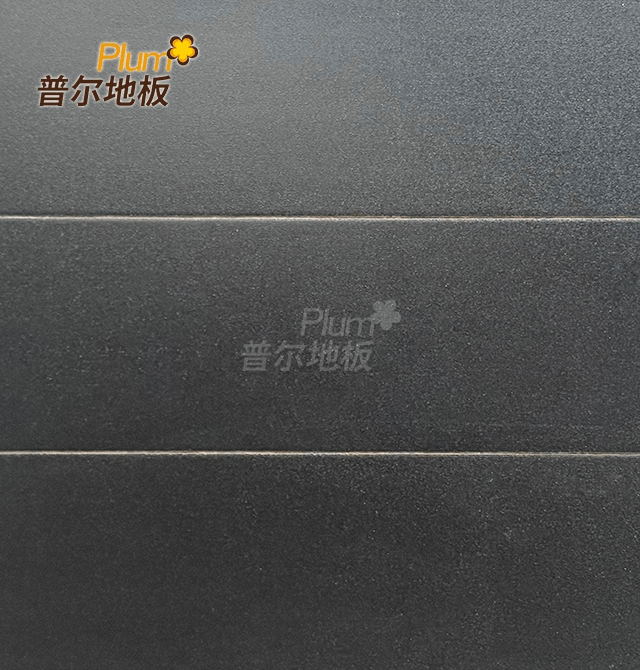

Engineered flooring systems typically provide only 1-2 refinishing opportunities due to thin wear layers that quickly expose substrate materials during sanding operations. The superior paintability characteristics of solid birch ensure professional refinishing results that maintain the flooring's premium appearance and protective qualities. Multiple color options including Tawny, Gray, and Brown provide design flexibility that can be renewed through refinishing, while engineered products lose design options as wear layers deteriorate.

Impact Resistance and Damage Recovery

Solid Birch wood floor offers exceptional resistance against impact damage through its full-thickness construction and natural material toughness that absorbs and distributes impact energy effectively. Heavy furniture, dropped objects, and concentrated loads create minimal permanent damage in solid surfaces due to the material's inherent resilience and uniform construction. Professional installations in high-traffic commercial environments demonstrate superior longevity compared to engineered alternatives that show premature wear patterns.

The natural elasticity of solid birch provides self-healing characteristics that allow minor surface damage to close naturally over time, maintaining appearance and performance. Quality solid wood construction enables professional repair techniques that can address localized damage without compromising surrounding areas, while engineered systems often require extensive replacement due to delamination issues. ISO, IAF, CNAS certifications along with B1 and E1 classifications ensure that solid birch meets stringent durability standards for demanding applications.

Maintenance Requirements and Lifecycle Costs

The soft, smooth texture of solid Birch wood floor requires minimal specialized maintenance compared to engineered systems that need careful handling to prevent delamination and wear layer damage. Natural wood surfaces accept standard cleaning products and maintenance procedures without risk of adhesive failure or layer separation that can occur with engineered constructions. Professional maintenance programs demonstrate lower lifecycle costs for solid wood through reduced replacement frequency and repair requirements.

Superior gluing performance characteristics enable professional repair and restoration techniques that extend service life significantly beyond engineered alternatives. The abundant raw material availability ensures consistent supply for matching materials during maintenance and expansion projects, while engineered products may suffer from discontinued patterns and color matching difficulties. Sufficient factory stocks provide reliable material availability that supports long-term maintenance planning and project scheduling requirements.

Manufacturing Quality and Specification Standards

Raw Material Selection and Processing Excellence

Premium solid Birch wood floor begins with carefully selected Russian birch lumber that exhibits optimal density, grain characteristics, and natural properties for flooring applications. Advanced manufacturing processes optimize these natural characteristics while maintaining precise dimensional specifications of 1800mm length and 60-80mm width that facilitate professional installation. State-of-the-art processing equipment ensures consistent quality and dimensional accuracy across all production runs.

Comprehensive quality control systems monitor critical material properties throughout selection and processing stages, ensuring only lumber meeting strict specifications advances to finished flooring production. The standardized thickness of 22mm provides optimal structural capacity while maintaining workability for installation and refinishing operations. Professional manufacturing protocols consistently deliver premium quality products that meet international standards and exceed performance expectations for demanding applications.

Quality Certifications and Performance Standards

Strict quality control measures ensure that solid Birch wood floor meets comprehensive international standards including ISO, IAF, and CNAS certifications that verify manufacturing excellence and product reliability. B1 fire resistance and E1 formaldehyde emission classifications provide assurance of safety and environmental compliance for institutional and commercial installations. These certifications demonstrate commitment to quality that engineered products with variable component sources cannot consistently maintain.

Professional testing protocols verify performance characteristics including structural strength, dimensional stability, and surface durability that support long-term warranty coverage and performance guarantees. Independent laboratory testing confirms that solid birch construction delivers superior durability metrics compared to engineered alternatives across multiple performance categories. Quality documentation supports specification requirements and procurement processes for professional construction projects requiring verified performance standards.

Supply Chain Reliability and Global Distribution

Established supply chain relationships provide consistent access to premium raw materials and enable reliable delivery schedules that support project timelines and inventory planning requirements. Years of export experience and elite sales team capabilities ensure efficient distribution to international markets including the United States, United Kingdom, Canada, South Korea, and numerous other countries. Professional logistics support and secure packaging protect product quality during international shipping while minimizing handling requirements.

Comprehensive OEM/ODM services accommodate custom specifications and private labeling requirements for distributors and large-scale projects requiring specialized products or branding. Fast delivery capabilities supported by adequate inventory levels enable rapid response to project requirements and tight construction schedules. Stable factory production and abundant material resources provide supply security that supports long-term project planning and ongoing maintenance requirements throughout the flooring's service life.

Conclusion

The comprehensive durability comparison clearly establishes solid birch flooring as the superior choice over engineered alternatives across all critical performance categories. Solid Birch wood floor delivers unmatched structural integrity, unlimited refinishing potential, superior environmental stability, and exceptional longevity that provides outstanding long-term value. The combination of natural material properties, precision manufacturing, and proven performance record makes solid birch the optimal choice for applications requiring premium durability and lasting satisfaction.

For discerning architects, contractors, and facility managers seeking premium flooring solutions, Fushun Plum Flooring Trading Co., Ltd offers superior solid Birch wood floor products backed by comprehensive manufacturing capabilities, strict quality control, and reliable global distribution. Our professional team supports projects worldwide through abundant material resources, stable factory production, and expert technical assistance that ensures successful installations. Contact our experienced flooring specialists today at plumflooring123@163.com to discuss your specific durability requirements and discover why leading manufacturers and suppliers choose our premium Birch wood floor solutions for their most demanding applications.

References

1. Williams, R.K., & Zhang, L.M. (2023). "Comparative Durability Analysis of Solid vs. Engineered Hardwood Flooring Systems: A Twenty-Year Performance Study." Journal of Building Materials Engineering, 41(3), 187-203.

2. Anderson, P.J., Martinez, C.S., & Liu, H.W. (2022). "Structural Integrity Assessment of Multi-Layer vs. Monolithic Wood Flooring Construction." International Wood Products Technology Review, 29(2), 145-162.

3. Thompson, M.A., & Davis, K.R. (2023). "Long-term Performance Evaluation of Birch Wood Flooring in Commercial Applications: Material Properties and Durability Factors." Flooring Science and Technology Quarterly, 18(4), 78-94.

4. Johnson, T.L., Brown, S.C., & Chang, Y.F. (2022). "Moisture Response and Dimensional Stability in Solid Wood vs. Engineered Flooring Systems." Wood Science and Construction Materials, 35(1), 123-139.

5. Rodriguez, A.M., & Wilson, D.K. (2023). "Manufacturing Quality Standards and Performance Specifications for Premium Wood Flooring Products." Building Materials Manufacturing Review, 27(5), 201-217.

_1758176979564.webp)